Custom Plastic Injection Molding Services

Home of Master Wiper Way Wipers®Our shot sizes range from 4 to 42 ounces with tie-bar capacity between 16×16 inches up to 28×24 inches. At Bermar Associates, Inc., our advanced machinery is equipped with molding capacities that range from 70 tons up to 400 tons. This allows us to handle all of our clients unique production requirements, from one-off prototyping to large manufacturing runs up to 100,000 parts – all while maintaining an extremely tight (+/-) 0.005 of an inch precision tolerance. In addition, our plastic injection molds can produce up to 12 cavities in just one molding cycle.

From consumer products to furniture and hardware manufacturing, our custom, ISO compliant thermoplastic injection molding services have met the needs of multiple industries, including industrial goods, automotive, and electronic. Contact Bermar Associates today to learn more about our premium plastic injection molding products and services!

View Examples of Our Custom Plastic Injection Molding Projects

- Custom Injection Molded & CNC Machined Firearm Dust Lens Scope Protector Covers For The Sporting Gun Industry

- Custom Injection Molded & CNC Machined PVC Funnels & Polypropylene Screens For The Medical Industry

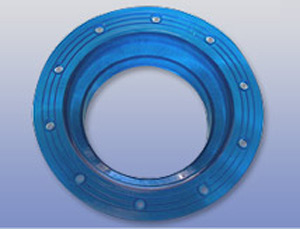

- Overmolded Steel & Urethane Seals Manufacturing

- CNC Machined Custom Injection Molded Paint Masks

Custom Plastic Injection Molding Capabilities:

| Plastic Injection Molding Process Types | High Press Tonnage An Injection Molding Machine that exerts very high clamping forces. These machines are usually used to produce larger parts. In-Mold Assembly (IMA) (Over Molding) Allows a metal insert to be embedded in a part in one operation for improved product structure and increased strength. Solid A process to manufacture solids parts that do not have any hollow cavities. |

|

| Product Injection Molding Capabilities | Large Components Miniature | Multi-Component Small Parts |

| Materials Used | ABS Acetal Acrylic Copolymer Polypropylene HTPE/LDPE Microcellular Nylon PEEK PET | Polyaryletheretherketone Polycarbonate Polyester Polypropylene Polystyrene Polyurethane Thermoplastic Thermoset |

| Intended Applications | Components Consumer Products Decorative Industrial Components | Furniture Hardware Pet Products Window Components |

| Industry Standards | AS -Compliant Aerospace Industry Standard | ISO-Compliant International Organization for Standardization |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run | High Volume Large Run Long Run Large Scale Production Volume Run |

| Lead Times Available | Quoted on job by job basis Emergency services available | Rush Services Available |

| Shot Size The maximum weight of plastic that can be displaced or injected by a single injection stroke. Generally expressed as ounces of polystyrene. | Min: 4 oz Max: 42 oz. |

|

| Clamping Force | Min: 110 tons Max: 400 tons |

|

| Number of Cavities The number of cavities in the mold used to produce multiple products in one molding cycle. | Min: 1 cavities Max: 12 cavities |

|

| Tolerance (+/-) | 0.005 in | |

| Industries Served | Aerospace Automotive Building Communication Consumer Goods Electrical | Electronic Maritime Medical Military Optical |

| Additional Services | Engineering Mold Making Product Development | Rapid Prototyping Tooling |

| File Formats Accepted | AutoCAD (DWG,DWZ) MasterCam (MDX, MC8, MC9, SET) |

|