Master Wipe® Way Wipers

Without Master Wipe® Way Wipers, your machine could have dirty ways! Way wipers are similar to the wipers on your car windshield. Just as they wipe the rain and snow from your windshield for clear visibility, way wipers protect machine ways from dirt, grinding dust, metal chips, and excess oils for smooth and efficient movement. Ways serve as guides for movable parts on a machine. As the movable parts travel across the ways, they must be kept clean in order for the machine to operate properly. Excess debris can impede maximum performance of a machine’s operation and even cause damage to the ways. To ensure the longevity of the ways and avoid costly repairs, way wipers need to be replaced on a regular basis.

For over 40 years, Master Wipe® Way Wipers have been the first choice for machine way protection. Master Wipe® Way Wipers afford machinery builders longer-lasting, more economical and more efficient wipers than any of our competitors. Master Wipe Way Wipers, have the capability to withstand most corrosive fluids and sprays, Master Wipe® remains an industry standard. They are made from a special blend of polyurethane and require metal chip deflectors only for hot applications and certain hole pattern specifications. It is no surprise that original equipment manufacturers (OEMs) and machinery rebuilders continue to order the wiper, which can endure the wear and tear of daily production.

Now Available:

Try our new wiper material with a higher resistance to water-soluble chemical coolants. Just another way that Master Wipe® continues to provide innovative products!

We invite you to sample our product. Contact us by e-mail, fax or telephone for a Master Wipe® sample that meets your way specifications. Discover what a quality wiper can do for your machines. Volume discounts are available.

Custom Master Wipe® Way Wipers

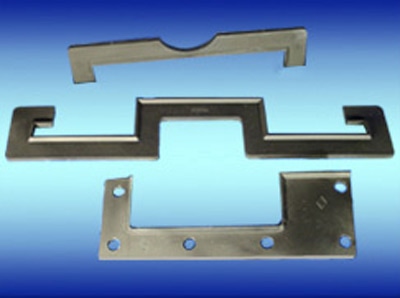

Master Wipe® custom way wipers are a 40-year tradition at Bermar Associates, Inc. We specialize in designing way wipers to meet your machine specifications. A vast range of unique features from multi-level to multi-faceted wiper lip configurations are displayed in the pictures below. For your application needs, we can vary the raw material hardness and add molybdenum (moly) for greater lubrication and lower coefficient of drag on your machine ways. Plus, we pride ourselves on creating wiper systems that offer interchangeable parts, such as right-hand and left-hand components, intricate corners, molded metal inserts, and metal stiffeners which can be assembled on the wiper. Our cost-effective methods, including tooling and machining, will meet the most economical budget. Whether your needs are for 1 or 100 wipers, contact us for a personalized quotation.

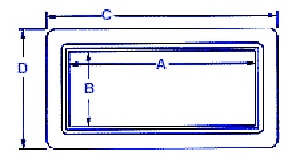

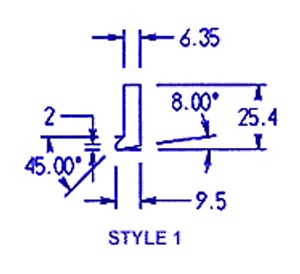

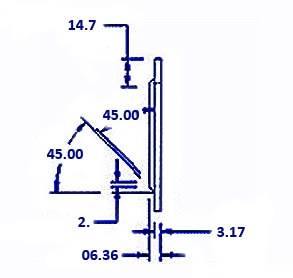

Master Wipe® Dovetail Wipers

Master Wipe® dovetail wipers are designed for a close fit on dovetail ways. Each dovetail wiper can be used for inside or outside ways. Our dovetail wipers are preset to minus .015/.020 (A-B) with fitting stock added to the ends for your individual needs. Upon request, truss head screws (1/4-20 x 5/8) will be furnished at no additional charge. Master Wipe® dovetail wipers are engineered for maximum endurance and quality.

| Model No. | A | B | C | D |

|---|---|---|---|---|

| WD-37 | .375 | 1.125 | 2.25 | .375 |

| WD-50 | .5 | 1.6875 | 3.5 | .625 |

| WD-62 | .625 | 2 | 4.25 | .75 |

| WD-75 | .75 | 3 | 6.5 | 1 |

| WD-87 | .875 | 3.125 | 6.5 | 1 |

| WD-100 | 1 | 3.5 | 7 | 1 |

| WD-125 | 1.25 | 4 | 8 | 1 |

| WD-150 | 1.5 | 4.75 | 9.25 | 1 |

| WD-175 | 1.75 | 5.5 | 10.25 | 1 |

| WD-200 | 2 | 5.5 | 10.25 | 1 |

Master Wipe® Metric Wipers

| Model No. | A | B | C | D |

|---|---|---|---|---|

| 9535 | 95 | 35 | 145.8 | 85.8 |

| 10070 | 100 | 70 | 150.8 | 120.8 |

| 110100 | 110 | 100 | 160.0 | 150.0 |

| 11040 | 110 | 40 | 160.8 | 90.8 |

| 12050 | 120 | 50 | 170.8 | 100.8 |

| 12750 | 127 | 50 | 177.8 | 100.8 |

| 15030B* | 150 | 30 | 203 | 80.8 |

| 15055 | 150 | 55 | 200.8 | 105.8 |

| 15060 | 150 | 60 | 200.8 | 110.8 |

All units are mm. *Denotes wiper has a 1.5 chamber in corners of wiping area and two sides of border are 26.97 wide.

| Model No. | A | B | C | D |

|---|---|---|---|---|

| 2424B* | 24 | 24 | 48 | 48 |

| 4040B* | 40 | 40 | 69.4 | 69.4 |

| 9930 | 99 | 30 | 128.4 | 59.4 |

| 15050 | 150 | 50 | 179.4 | 79.4 |

| 22650 | 226 | 50 | 255.4 | 79.4 |

Rectangular Master Wipe® Way Wipers 1" to 3" Width

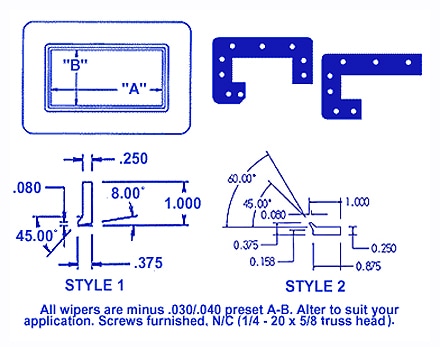

Unsurpassed in durability and quality, Master Wipe® rectangular wipers are stocked for most standard sizes of way bars. Special sizes, hole patterns, left and right wiper mates, and other custom designs can be produced to suit your application. All rectangular wipers are preset to minus .030/.040 (A-B). Mounting screws (1/4-20 x 5/8 truss head) are furnished at no extra charge upon request.

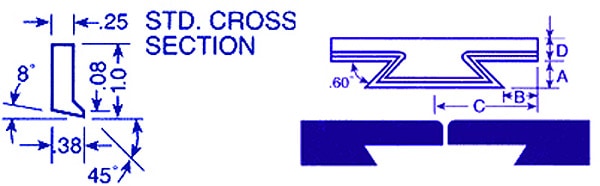

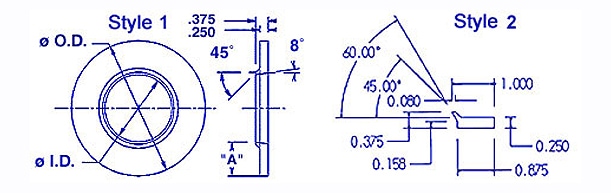

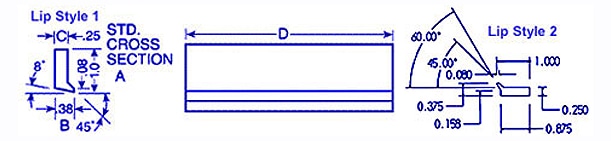

An optional style wiping lip is a feature unique to Master Wipe® rectangular way wipers. Two styles are offered for your machine ways. Style 1 is our standard wiping lip. It provides firm wiping with a thick lip that forms an 8° angle. For those wiping operations requiring low pressure and reduced drag, the Style 2 wiping lip would be a suitable choice. This thin-lip style forms a 45° angle. Style 2 allows greater flexibility on the wiping edge, while maintaining maximum performance. The drawings below offer greater detail to help you make the proper selection.

| Model No. | A | B |

|---|---|---|

| 1212B* | 1.25 | 1.25 |

| 1507 | 1.5 | .75 |

| 1515 | 1.5 | 1.5 |

| 1707 | 1.75 | .75 |

| 1710 | 1.75 | 1 |

| 1710B* | 1.75 | 1 |

| 1712 | 1.75 | 1.25 |

| 2007 | 2 | .75 |

| 2008 | 2 | .875 |

| 2010 | 2 | 1 |

| 2011B* | 2 | 1.125 |

| 2012 | 2 | 1.25 |

| 2020 | 2 | 2 |

| 2110 | 2.125 | 1 |

| 2111 | 2.125 | 1.125 |

| 2117 | 2.125 | 1.75 |

| 2210 | 2.25 | 1 |

| 2212 | 2.25 | 1.25 |

| 2311 | 2.375 | 1.125 |

| 2312 | 2.375 | 1.25 |

| 2315 | 2.375 | 1.5 |

| 2510 | 2.5 | 1 |

| 2511 | 2.5 | 1.125 |

| 2512 | 2.5 | 1.25 |

| 2513 | 2.5 | 1.375 |

| Model No. | A | B |

|---|---|---|

| 2515 | 2.5 | 1.5 |

| 2525 | 2.5 | 2.5 |

| 2712 | 2.75 | 1.25 |

| 27130 | 2.75 | 1.3125 |

| 2717 | 2.75 | 1.75 |

| 2727 | 2.75 | 2.75 |

| 2812 | 2.875 | 1.25 |

| 2813 | 2.875 | 1.375 |

| 2815 | 2.875 | 1.5 |

| 2828 | 2.875 | 2.875 |

| 3007 | 3 | .75 |

| 3007B* | 3 | .75 |

| 3010 | 3 | 1 |

| 3012 | 3 | 1.25 |

| 3013 | 3 | 1.375 |

| 3015 | 3 | 1.5 |

| 3023 | 3 | 2.375 |

| 3025 | 3 | 2.5 |

| 3030 | 3 | 3 |

| 3113 | 3.125 | 1.375 |

| 3212 | 3.25 | 1.25 |

| 3213 | 3.25 | 1.375 |

| 3215 | 3.25 | 1.5 |

| 3220 | 3.25 | 2 |

| 33017 | 3.3125 | 1.75 |

| Model No. | A | B |

|---|---|---|

| 3311 | 3.375 | 1.125 |

| 3313 | 3.375 | 1.375 |

| 3315 | 3.375 | 1.5 |

| 3316 | 3.375 | 1.625 |

| 3317 | 3.375 | 1.75 |

| 3508 | 3.5 | .875 |

| 3511 | 3.5 | 1.125 |

| 35106 | 3.5 | 1.0625 |

| 3512 | 3.5 | 1.25 |

| 3513 | 3.5 | 1.375 |

| 3515 | 3.5 | 1.25 |

| 3516 | 3.5 | 1.625 |

| 3517 | 3.5 | 1.75 |

| 3520 | 3.5 | 2 |

| 3525 | 3.5 | 2.5 |

| 3615 | 3.625 | 1.5 |

| 3620 | 3.625 | 2 |

| 3712 | 3.75 | 1.25 |

| 3713 | 3.75 | 1.375 |

| 3715 | 3.75 | 1.5 |

| 3717 | 3.75 | 1.75 |

| 3720 | 3.75 | 2 |

| 3722 | 3.75 | 2.25 |

| 38081 | 3.875 | .8125 |

| 3810 | 3.875 | 1 |

| 3811 | 3.875 | 1.125 |

* Denotes nonstandard wiper

Rectangular Master Wipe® Way Wipers 4" to 12" Width

Unsurpassed in durability and quality, Master Wipe® rectangular wipers are stocked for most standard sizes of way bars. Special sizes, hole patterns, left and right wiper mates, and other custom designs can be produced to suit your application. All rectangular wipers are preset to minus .030/.040 (A-B). Mounting screws (1/4-20 x 5/8 360″ truss head) are furnished at no extra charge upon request.

An optional style wiping lip is a feature unique to Master Wipe® rectangular way wipers. Two styles are offered for your machine ways. Style 1 is our standard wiping lip. It provides firm wiping with a thick lip that forms an 8° angle. For those wiping operations requiring low pressure and reduced drag, the Style 2 wiping lip would be a suitable choice. This thin-lip style forms a 45° angle. Style 2 allows greater flexibility on the wiping edge, while maintaining maximum performance. The drawings below offer greater detail to help you make the proper selection.

| Model No. | A | B |

|---|---|---|

| 4010 | 4 | 1 |

| 4012 | 4 | 1.25 |

| 4015 | 4 | 1.5 |

| 4016 | 4 | 1.625 |

| 4017 | 4 | 1.75 |

| 4017B* | 4 | 1.75 |

| 4020 | 4 | 2 |

| 4020B* | 4 | 2 |

| 4025 | 4 | 2.5 |

| 4030 | 4 | 3 |

| 4040 | 4 | 4 |

| 4215 | 4.25 | 1.5 |

| 4217 | 4.25 | 1.75 |

| 4220 | 4.25 | 2 |

| 4515 | 4.5 | 1.5 |

| 4517 | 4.5 | 1.75 |

| 4520 | 4.5 | 2 |

| 4521 | 4.5 | 2.125 |

| 4522B* | 4.5 | 2.25 |

| 4530 | 4.5 | 3 |

| 4715 | 4.75 | 1.5 |

| 4717 | 4.75 | 1.75 |

| 4718 | 4.75 | 1.875 |

| 4720 | 4.75 | 2 |

| 47216 | 4.75 | 2.15625 |

| 4722 | 4.75 | 2.25 |

| Model No. | A | B |

|---|---|---|

| 4725 | 4.75 | 2.5 |

| 4737 | 4.75 | 3.75 |

| 4747 | 4.75 | 4.75 |

| 4820 | 4.875 | 2 |

| 4825 | 4.875 | 2.5 |

| 5012 | 5 | 1.25 |

| 5013B* | 5 | 1.375 |

| 5015 | 5 | 1.5 |

| 5017 | 5 | 1.75 |

| 5020 | 5 | 2 |

| 5022 | 5 | 2.25 |

| 5025 | 5 | 2.5 |

| 5040 | 5 | 4 |

| 5216 | 5.25 | 1.625 |

| 5225 | 5.25 | 2.5 |

| 5522B* | 5.5 | 2.25 |

| 5525 | 5.5 | 2.5 |

| 5530 | 5.5 | 3 |

| 5616 | 5.625 | 1.625 |

| 5712 | 5.75 | 1.25 |

| 5727 | 5.75 | 2.75 |

| 5730 | 5.75 | 3 |

| 6015B* | 6 | 1.5 |

| 6020 | 6 | 2 |

| 6022 | 6 | 2.25 |

| 6025 | 6 | 2.5 |

| Model No. | A | B |

|---|---|---|

| 6030 | 6 | 3 |

| 6060 | 6 | 6 |

| 6210 | 6.25 | 1 |

| 6525 | 6.5 | 2.5 |

| 6526 | 6.5 | 2.625 |

| 6526B* | 6.5 | 2.625 |

| 6735 | 6.75 | 3.5 |

| 7015 | 7 | 1.5 |

| 7020 | 7 | 2 |

| 7025 | 7 | 2.5 |

| 7025B* | 7 | 2.5 |

| 7030 | 7 | 3 |

| 7326 | 7.375 | 2.625 |

| 7512 | 7.5 | 1.25 |

| 7525 | 7.5 | 2.5 |

| 7820 | 7.875 | 2 |

| 7931 | 7.9375 | 3.125 |

| 8020B* | 8 | 2 |

| 8030 | 8 | 3 |

| 8031 | 8 | 3.125 |

| 8035 | 8 | 3.5 |

| 8510B* | 8.5 | 1 |

| 8553 | 8.5 | 5.375 |

| 9710 | 9.75 | 1 |

| 10030 | 10 | 3 |

| 10060 | 10.0 | 6.0 |

| 12816 | 12.875 | 1.625 |

Round Bar Master Wipe® Way Wipers

| Model No. | Bar Dia. | I.D. | O.D. | A |

|---|---|---|---|---|

| RD-.750 | .75" | .750 | 2.250 | .750 |

| RD-1.000 | 1" | 1.000 | 2.500 | .750 |

| RD-1.250 | 1.25" | 1.250 | 2.750 | .750 |

| RD-1.375 | 1.375" | 1.375 | 2.880 | .750 |

| RD-1.500 | 1.5" | 1.500 | 3.000 | .750 |

| RD-1.625 | 1.625" | 1.625 | 3.125 | .750 |

| RD-1.750 | 1.75" | 1.750 | 3.250 | .750 |

| RD-2.000 | 2" | 2.000 | 3.500 | .750 |

| RD-2.500 | 2.5" | 2.500 | 4.000 | .750 |

| RD-2.750 | 2.75" | 2.750 | 4.500 | .875 |

| RD-3.000 | 3" | 3.000 | 4.500 | .750 |

| RD-3.250 | 3.25" | 3.250 | 5.000 | .875 |

| RD-3.500 | 3.5" | 3.500 | 5.500 | 1.000 |

| RD-4.000 | 4" | 4.000 | 5.500 | .750 |

| RD-5.000 | 5" | 5.000 | 7.000 | 1.000 |

| RD-5.500 | 5.5" | 5.500 | 7.350 | .925 |

| RD-6.000 | 6" | 6.000 | 8.000 | 1.000 |

| RD-6.500 | 6.5" | 6.500 | 8.500 | 1.000 |

| RD-6.750 | 6.75" | 6.750 | 8.750 | 1.000 |

| RD-7.000 | 7" | 7.000 | 9.000 | 1.000 |

| RD-8.000 | 8" | 8.000 | 10.000 | 1.000 |

Straight Strip Master Wipe® Way Wipers

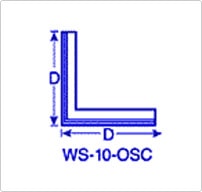

Master Wipe® straight strip wipers can be provided in any length, per your specifications, up to eight feet. Standard strips are one inch wide with a preset of minus .015/.020 (A-B). Other widths are available (see chart below). Truss head screws (1/4-20 x 5/8) are furnished at no additional charge upon request. Strip deflectors can be mated to the wiper strips in sizes up to four feet in length.

NOTE: Strip Chip Deflectors available upon request in most sizes. All wipers are minus .030/.040 preset A-B. Alter to suit your application. Screws furnished upon request, N/C (1/4 – 20 x 5/8 truss head). Style 2 lip design available up to 24″ long.

| Model No. | A | B | C | D |

|---|---|---|---|---|

| WS-10 x 8' | 1.00 | .38 | .25 | 8' |

| WS-10 x 24" | 1.00 | .38 | .25 | 24" |

| WS-10 x 32" | 1.00 | .38 | .25 | 32" |

| WS-10 x 48" | 1.00 | .38 | .25 | 48" |

| WS-12 | 1.25 | .38 | .25 | 24" |

| WS-15 | 1.50 | .38 | .25 | 24" |

| WS-17 | 1.75 | .38 | .25 | 24" |

| WS-20 | 2.00 | .38 | .25 | 24" |

| WS-25 | 2.50 | .38 | .25 | 24" |

| WS-30 | 3.00 | .38 | .25 | 24" |

| WS-2558 | .50 | .25 | .13 | 8" |

| WS-10-OSC | 1.00 | .38 | .25 | 6" |

Master Wipe® V-Wipers

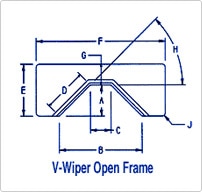

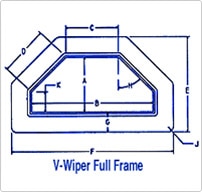

Master Wipe® V-Wipers are designed to fit a variety of V-shaped ways. A firm wiping edge keeps the machine way clean and free from debris. Two types are offered: V-Open Frame (VOF) and V-Full Frame (VFF). In addition to the stock sizes shown below, custom V-Wipers can be made to suit your specifications. Stock V-Wipers are available in Style 1 lip design only (see rectangular wipers). Custom lip designs quoted upon request.

| Model No. | A | B | C | D | E | F | G | H | J | K |

|---|---|---|---|---|---|---|---|---|---|---|

| VFF-10 | 1.250 | 2.000 | .500 | 1.080 | 3.175 | 3.925 | 1.000 | 45° | .187R | .500 |

| VFF-20 | 1.750 | 3.750 | 1.625 | 1.562 | 3.150 | 5.750 | 1.000 | 45° | .375R | .687 |

| VFF-30 | 2.000 | 4.000 | .937 | 2.125 | 4.000 | 6.000 | 1.000 | 45° | .250R | .500 |

| VFF-40 | 2.437 | 3.500 | .500 | 2.125 | 4.500 | 5.500 | 1.000 | 45° | .187R | 1.000 |

| VFF-45 | 2.750 | 4.000 | .500 | 2.480 | 4.500 | 5.750 | .875 | 45° | .250R | 1.000 |

| VFF-50 | 2.500 | 5.500 | 1.625 | 2.750 | 4.500 | 7.500 | 1.000 | 45° | .125R | .575 |

| VFF-60 | 2.500 | 5.500 | 2.000 | 2.500 | 4.500 | 7.450 | 1.000 | 45° | .125R | .710 |

| VOF-10(SW-45) | .750 | 1.625 | .125 | 1.062 | 1.730 | 2.220 | 1.000 | 45° | .125R | - |

| VOF-20 | .875 | 2.000 | .250 | 1.230 | 1.875 | 5.400 | 1.00 | 45° | .187R | - |

| VOF-30 | 1.125 | 2.425 | .250 | 1.580 | 2.125 | 5.420 | 1.000 | 45° | .187R | - |